Heavily inspired by the iRSM Digital Design in Facial Prosthetics workshop in Edmonton, Canada this summer, my classmate Lindsay and I conducted a study on rapid prototyping a digitally designed 3-piece auricular prosthesis mold. We utilized an iCAT to obtain DICOM files of our ear casts and patient treatment site.

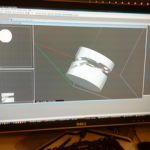

The DICOM files were then imported into Materialise Mimics to mirror the existing ear to adapt to the treatment surface. It was then booleoned from a larger cylinder and digitally designed into a 3-piece auricular mold with keyways to ensure proper fitting. A workflow was then created for the digital fabrication of the mold utilizing Mimics.

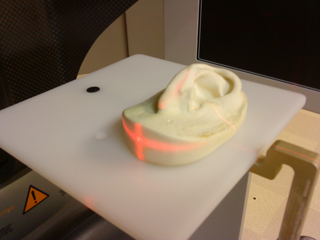

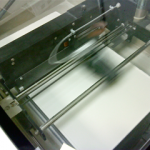

The STL of the completed mold was sent to a ZPrinter 310 Plus to be rapid prototyped with a high composite powder and binder.

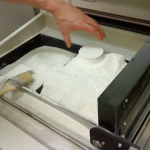

After printing, the mold was retrieved for postproduction work of drying, infiltrating with cyanoacrylate, and sanding for a final finish.

The prostheses fabricated from the rapid prototyped molds will be used to assess anatomical accuracies to the original ear casts and compared to the traditionally fabricated prostheses through wax sculpting. Another assessment will be made on time and cost effectiveness to determine its feasibility for clinical application.

Ridiculously cool.